CHEMICAL SOLUTIONS

For LED/Semiconductor process

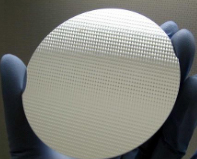

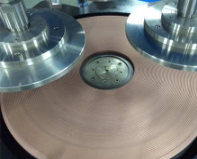

We develop and provide the most efficiently customized oil and water base diamond slurries

OIL/WATER BASE DIAMOND SLURRIES

DIAMOND TYPE : MONO, POLY, BLAST

Possible diamond powder size : 1.5-20um

POLISHING FOR SAPPHIRE WAFER AND

CERAMIC BASE PARTS

VISCOSTY, DIAMOND DISTRIBUTION RATE

CONTROL

OFFERING ANY CUMSTOMIZED

PRODUCTS

| Size | Median (D50) | Upper Limit (D99) |

|---|---|---|

| 2-4 μm | 3.12 μm | 6.20 μm |

| 3-6 μm | 4.27 μm | 8.29 μm |

| 3-7 μm | 5.17 μm | 10.02 μm |

| 4-8 μm | 6.38 μm | 12.3 μm |

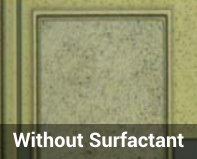

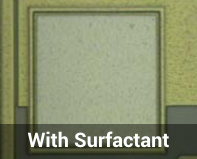

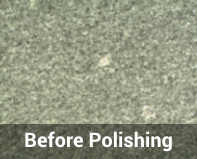

Wafer Backside Condition Before/After Polishing

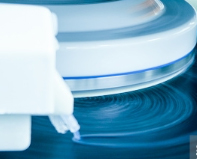

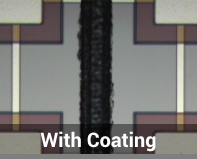

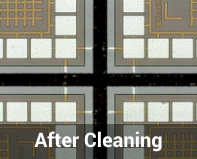

LASER DICING COATING SOLUTION

Water soluble material

Wafer surface spin coated before laser cutting

Easily cleaned with D.I. water

Stable coating layer

No debris and hazardous materials after laser cutting

SURFACTANT

Protect wafer from corrosion and particle contamination.

Reducing chipping and crack, improving blade life time Low consumption by dilution